공급망공학연구실

> 연구분야 > 공급망공학연구실

> 연구분야 > 공급망공학연구실

- 연구실명

- 공급망공학연구실 (Supply Chain Engineering Lab.)

- 담당교수

- 김태복

- 연구실위치

- 한양대학교 서울캠퍼스 공업센터 본관 715-2

- 연구분야

-

- 1. Development of Optimization Models for Supply Chain Integration

- Uncovering new areas for intelligent supply chain system

- Adoption of new technologies for supply chain optimization

- Advanced integration for Sustainable Closed-loop supply chain

- 2. Inventory Design for Supply Chain Strategies

- Strategical development for inventory design for assuring the competitive supply chain

- Optimized Product Variery Management

- Effective Product Lifecycle Management(New Product Introduction, End-Of-Life Management)

- 3. Human Factors in Advanced Logistics System

- Human-Machine Integration for logistics system

- Development of optimization model to integrated design for logistics system

- Consideration of physical - psychological aspects for logistics system design

- 연구실소개

-

1) Recent Research Articles (2017 ~)

- S. Sarmah*, A. Bhaskar and T. Kim (2019), Collaborative last-mile delivery and pick-up in city logistics for smart cities, Int. J. Logistics Systems and Management (Article in press)

- C. H. Glock, E.H. Grosse, T. Kim*, W.P. Neumann and A. Sobhani (2019) , An integrated cost and worker fatigue evaluation model of a packaging process, Int. J. Production Economics , Vol. 207, pp. 107 - 124.

- T. Kim*(2018), An integrated model for production and batch shipments for ramp-up production, Computers & Industrial Engineering, Vol. 118, pp. 138-152.

- T. Kim and C.H. Glock* (2018), Production planning for a two-stage production system with multiple parallel machines and variable production rates, Int. J. Production Economics , Vol. 196, pp. 284 – 292.

- M. Sarkar, B.K. Shaw, T. Kim , B. Sarkar*, D. Shin (2017), Two-echelon supply chain model with variable transportation cost, two-stage inspections, and defective units , Journal of Industrial and Management Optimization, Vol. 13, Issue 4, pp. 1975- 1990.

- F. Beck*, C. H. Glock and T. Kim(2017), Coordination of a production network with a single buyer and multiple vendors with unequal-sized batch shipments , Int. J. Production Economics , Vol. 193, pp. 633- 646.

- L. Jian, W. Zhen, J. Bao and T. Kim*(2017) , Coordination strategies in a three-echelon reverse supply chain for economic and social benefit, Applied Mathematical Modeling, Vol. 49C, pp. 599 – 611.

2) Recent Industrial Projects

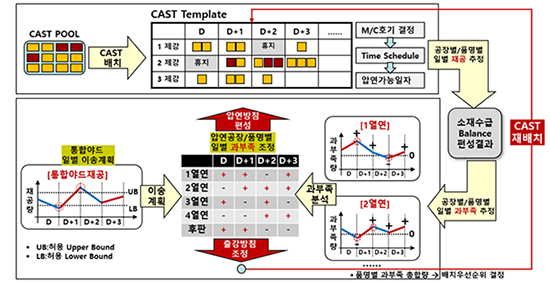

- Design of Production Diretives for POSCO MES 3.0 (Detailed design)

- In this project, our team deviloped a MILP(Mixed-INterger Linear Programming) optimization model in order to devilop the production direvtives for steel-making process in POSCO for two works, i.e, Pohang and Gwangyang. For optimzin the overall steel-making process, the intergrated model for multi-stage production system was developed. (TOOLS:CPLEX)

- Design of Producion Diretives for POSCO MES 3.0 (Concept design)

- In this consultancy project, our team tried to design the new approach to realizing the effective production directives to control steel-making production system to satisfy the given requirements and objectives more efficiently. (TOOLS:CPLEX, R)

- Devilopment of Supply Logistics Strategy Based on Big Data (Sponsored by USG Boral Korea)

- In order to develop the resonable and realizable supply logistics for the compay, a lot of data for manufacturing as well as sales are aggregated and the analyzed for the purpose of analyzign the status-quo of supply logistics network using R. Based on these sophisticated analyses, our team also proposed the effective and promosing strategies to help this company by realizing the effective supply logistics network. (TOOLS:R)

- Design of INventory Management Scheme for Wood Pellets

- It is one of critical problem in operaing power plant to keep the economical stocks i.e., wood pellets, which should be impoted from foreign countres through the multi-stage logistics network, which needs a inevitable long lead-time. Thus, the well-balanced inventory management scheme should be designed to control the inventories while keeping the utilization rate of power plant as well as lowering the inventory costs. (TOOLS:CPLEX, AutoMod)